American Standard for Unified Screw Threads

American Standard B1.1-1949 was the first American standard to cover those Unified Thread Series agreed upon by the United Kingdom, Canada, and the United States to obtain screw thread interchangeability among these three nations. These Unified threads are now the basic American standard for fastening types of screw threads. In relation to previous American practice, Unified threads have substantially the same thread form and are mechanically interchangeable with the former American National threads of the same diameter and pitch. The principal differences between the two systemslie in: 1) application of allowances; 2) variation of tolerances with size; 3) difference in amount of pitch diameter tolerance on external and internal threads; and 4) differencesin thread designation. In the Unified system an allowance is provided on both the Classes 1A and 2A external threads whereas in the American National system only the Class I external thread has an allowance. Also, in the Unified system, the pitch diametertolerance of an internal thread is 30 per cent greater than that of the external thread, whereasthey are equal in the American Nationalsystem. Revised Standard.—The revised screw thread standard ANSI/ASME B1.1-1989 (R2001) is much the same as that of ANSI B1.1-1982. The latest symbols in accordance with ANSI/ASME B1.7M-1984 (R2001) Nomenclature, are used. Acceptability criteria are described in ANSI/ASME B1.3M-1992 (R2001), Screw Thread Gaging Systems for Dimensional Acceptability, Inch or Metric Screw Threads(UN, UNR, UNJ, M, and MJ). Where the letters U, A or B do not appear in the thread designations, the threads conform to the outdated American Nationalscrew threads.

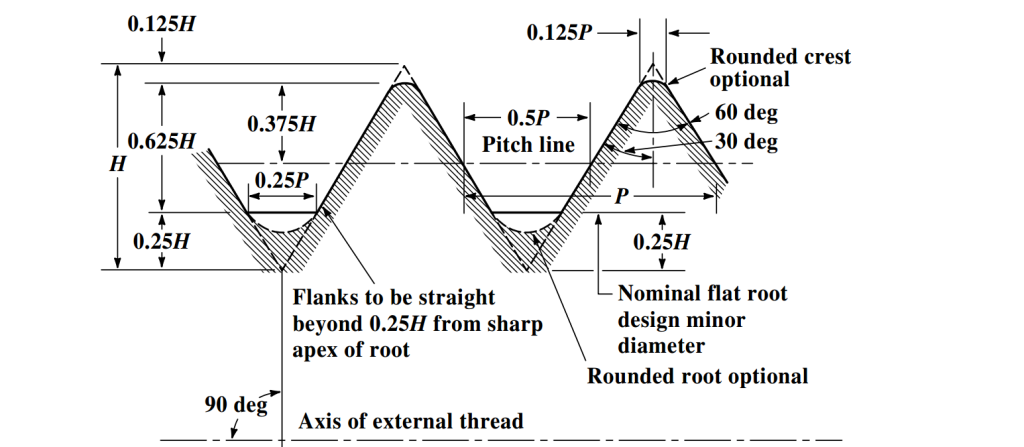

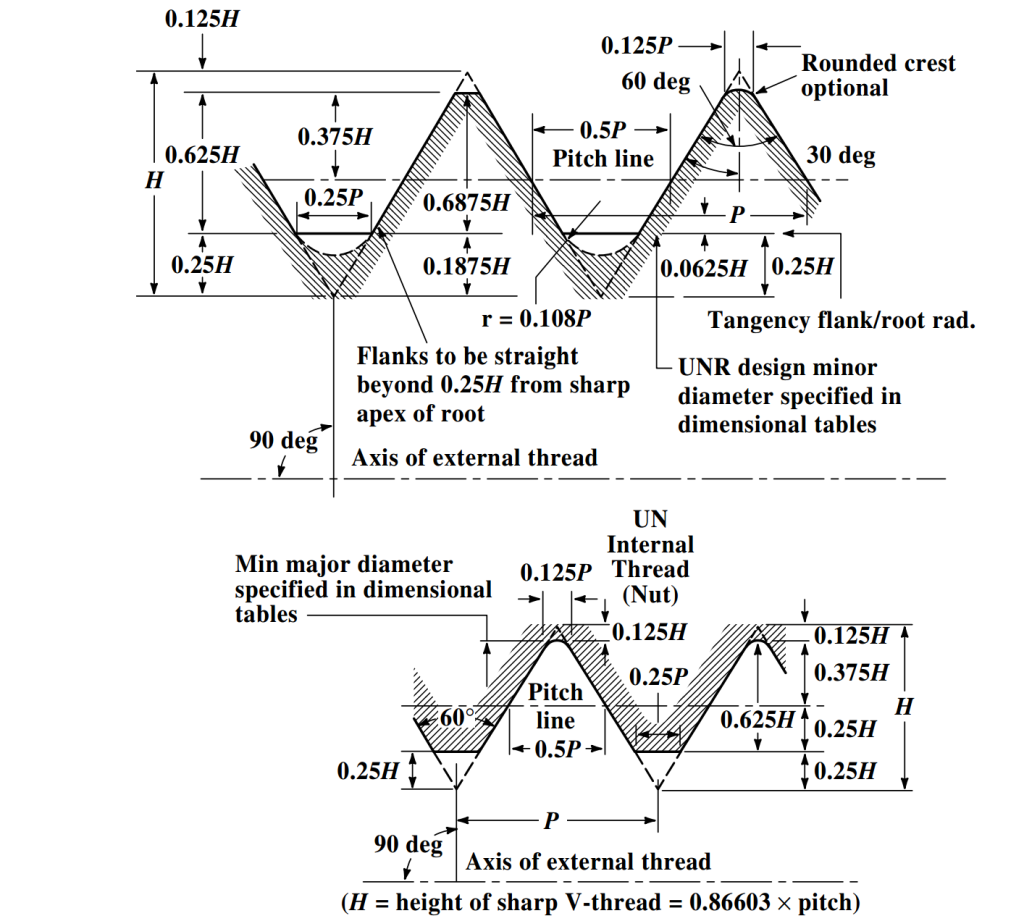

Advantages of Unified Threads.—The Unified standard is designed to correct certain production difficultiesresulting from the formerstandard. Often, under the old system, the tolerances of the product were practically absorbed by the combined tool and gage tolerances, leaving little for a working tolerance in manufacture. Somewhat greater tolerances are now provided for nut threads. As contrasted with the old “classes of fit” 1, 2, and 3, for each of which the pitch diameter tolerance on the external and internal threads were equal, the Classes 1B, 2B, and 3B (internal) threads in the new standard have, respectively, a 30 per cent larger pitch diameter tolerance than the 1A, 2A, and 3A (external) threads. Relatively more tolerance is provided for fine threadsthan for coarse threads of the same pitch. Where previoustolerances were more liberal than required, they were reduced. Thread Form.—The Design Profiles for Unified screw threads, shown on page 1720, define the maximum material condition for external and internal threads with no allowance and are derived from the Basic Profile,shown on page 1713. UN External Screw Threads: A flat root contour is specified, but it is necessary to provide for some threading tool crest wear, hence a rounded root contour cleared beyond the 0.25P flat width of the Basic Profile is optional. UNR External Screw Threads: To reduce the rate of threading tool crest wear and to improve fatigue strength of a flat root thread, the Design Profile of the UNR thread has a smooth, continuous, non-reversing contour with a radius of curvature not lessthan 0.108P at any point and blends tangentially into the flanks and any straightsegment. At the maximum material condition, the point of tangency is specified to be at a distance not less than 0.625H (where H isthe height of a sharp V-thread) below the basic major diameter. UN and UNR External Screw Threads: The Design Profiles of both UN and UNR externalscrew threads have flat crests. However, in practice, product threads are produced with partially or completely rounded crests. A rounded crest tangent at 0.125P flat is shown as an option on page 1720.

UN Internal Screw Thread: In practice it is necessary to provide for some threading tool crest wear, therefore the root of the Design Profile is rounded and cleared beyond the 0.125P flat width of the Basic Profile.There is no internal UNR screw thread.

Thread Series.—Thread series are groups of diameter-pitch combinations distinguished from each other by the numbers of threads per inch applied to a specific diameter. The various diameter-pitch combinations of eleven standard series are shown in Table 2. The limits of size of threads in the eleven standard series together with certain selected combinations of diameter and pitch, as well as the symbols for designating the various threads, are given in Table 3. (Text continues on page 1750)